Your cart is currently empty!

- Custom build bikes

- Customized advice

- Lifetime warranty*

- Unique Dutch design

14CARBON develops and manufactures road and gravel bikes for elite athletes and passionate enthusiasts. Our customers use their 14CARBON bikes to make a statement, train and race. Every bike we build is unique and personal.

What goal do you want to achieve with your 14CARBON bike?

14CARBON is an innovative bicycle brand that has its origins in the renowned nanotech company Nano Composites Applied Technologies BV, based in Koudum. This company combines advanced technologies and material science to develop unique race and gravel bikes that push boundaries in performance and durability.

Our journey began with a focus on carbon’s biggest drawback: its fragility. Carbon is light and stiff, but often lacks the strength needed for optimal durability. In the search for improvements, we turned to innovative materials such as graphene and polyaramide. Although graphene showed impressive properties, it did not meet all expectations. Therefore, we turned to crystalline polyaramide, a nanofiber that had already proven its strength and reliability in applications such as bulletproof vests.

In 2019, this approach resulted in our first homemade frame, a combination of carbon fiber and polyaramide. This design, a cyclo/gravel bike, was developed in collaboration with Aalto University in Finland. Our next project, an advanced AERO road bike, was co-designed by Richard MacAinsh, a former Formula 1 designer. Thus was born a unique line of bikes designed with precision and craftsmanship.

To make production scalable, we switched to producing our carbon frames in China since 2020. In 2022, the first frames with our revolutionary XCR technology saw the light of day. This technology combines carbon fiber and polyaramid fiber in one product and offers unprecedented strength and stiffness. The idea has been patented and is at the heart of our future plans.

At 14CARBON, we continue to innovate and strive for independence by manufacturing base chemicals and fibers in Europe. This allows us to maintain full control over the quality and performance of our materials. Our goal is to create a sustainable and high-quality future for racing and gravel bikes, driven by technology and passion.

In addition to graphene and polyaramide, we also work with other nanomaterials in, for example, our own bicycle paints and coatings. Here we look primarily at function. Think of wear resistance, water and dirt repellency, low-scratch and even building solar cells into a paint is among the functions we are considering. We have listed a few projects for you where we will be focusing on in the near future.

These new generation resins produced in Germany are our basis for in-house developed bicycle lacquers. They are paints produced largely without petroleum and they are also extremely fast-drying two-pack paints. Polysiloxane lacquers are currently widely used in shipping because they are environmentally friendly, wear-resistant and durable paint systems: they are also the basis for our own developed lacquers.

Both materials are among the ingredients that make lacquers harder and thus more scratchy. Both are some well-known examples of extremely hard materials, close to the hardness of diamond. Some bikes with these so-called ceramic lacquers have already been delivered: after a year of intensive cycling there was not a single scratch on them! Ask us about the possibilities or check in our shop whether you can also get your bike in a low-scratch coating. Please note that the number of colors is still limited!

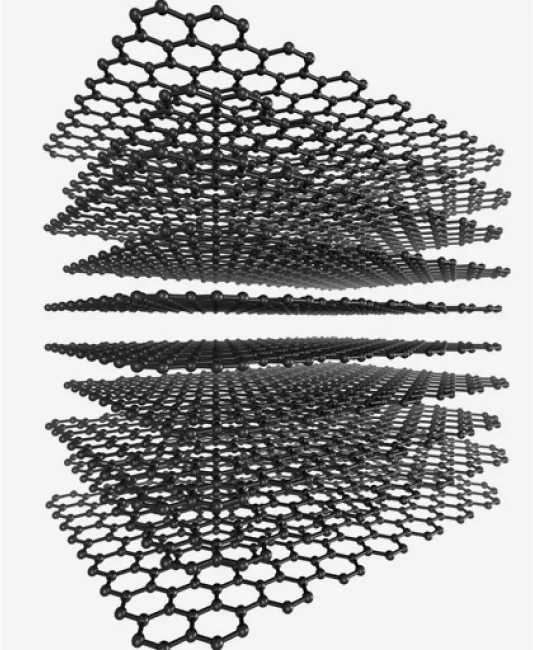

We apply graphene in lacquers that we want to make conductive, antibacterial, stronger or for the sake of color dark. Graphene is itself a fat material and also remotely resembles graphite. If you sand the paint with graphene or graphite, you get that characteristic pencil effect. Graphene seems to have lost its usefulness as a reinforcing material; for reinforcement of resins, graphene’s little brother is much more interesting: carbon nano tube (CNT). Well-known applications of graphene and CNT in products are Vittoria’s tires: rubber lasts longer, it is more wear-resistant. Graphene and CNT are also used in car tires.

Not to be confused with polysiloxane, this polymer is the basis of what is also commercially called “glass coat. Today, more materials are covered by these also called water repellent coatings, think titanium dioxide sprays. We have developed our own formula of nanomaterials in a spray-ready coating, technically you can spray the entire bike or car with it. A 5-10micron thick invisible layer forms that protects and prolongs the paint or carbon. The layer is also a strong UV filter. Polysilazanes are polymers of silicon chains and are reactive to most paint or plastic surfaces. This means that it chemically adheres to the substrate, you can compare it to permanent wax. The resulting layer resembles glass, a network of “Si-O-Si-O” molecules. Its characteristic is just like glass: it is hard, which is why it is also called ceramic coating, and it is water-repellent. Another advantage is that it is also aerodynamic.

Great offers, news and trends - free in your mailbox.

Select one of our specialists